This site uses non-intrusive cookies to enable us to provide a better user experience for our visitors. No personal information is collected or stored from these cookies. The Society's policy is fully explained here. By continuing to use this site you are agreeing to the use of cookies.

The Laboratory, opened in December 1935 by Lord Rutherford of Nelson, consists of a two-storey laboratory block and a single-storey workshop block. The building accommodates the Metallurgical, Engineering, Paint and Textile Sections of the Research Department, and these sections possess well defined spheres of activity, particularly in regard to what may be termed routine work, but in many research investigations co-operation is essential, and this is now greatly facilitated by the sections being housed under the same roof. It may be recalled that the Chemical Section still maintains separate laboratories at Crewe, Derby, Horwich and Glasgow, whilst the Physics Section is located at St. Pancras Chambers.

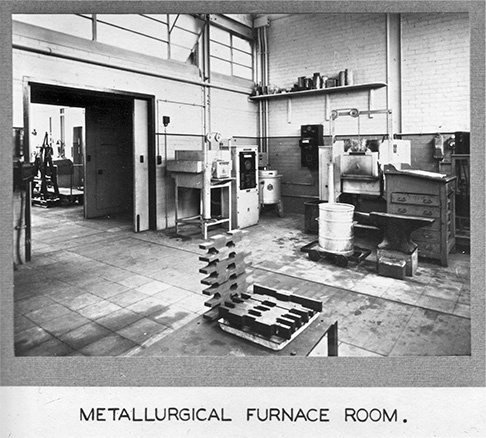

The Metallurgical Section is concerned with investigations relating to the selection and manipulation, by casting, forging, heat treatment, welding etc., of metals used throughout the Company, and for the metallurgical examination of materials that have failed to give satisfactory performance in service.

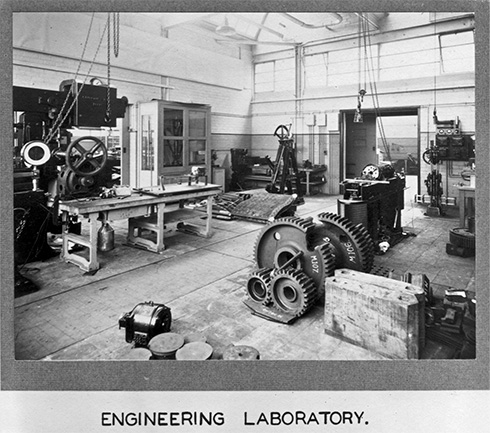

The Engineering Section deals with research on the design and performance of engineering details of machines and structures, and with the mechanical properties of materials in relation to service requirements. It is also responsible for the investigation into the mechanical aspects of failures of materials in service and for the study of aero-dynamical problems in the wind tunnel connected with the air resistance of trains, wind pressures, ventilation systems, etc. The work is carried out partly in the laboratory and partly, with the co-operation of other Departments, in the field.

The Textile Section is responsible for the inspection and testing of the various textile materials purchased by the Company, and for drawing up specifications controlling their quality. This routine work is on a considerable scale, some 8,000 complete tests being carried out each year. In addition, investigations into performance are carried out in the laboratory and in the field, and research on new materials and processes are required from time-to-time.

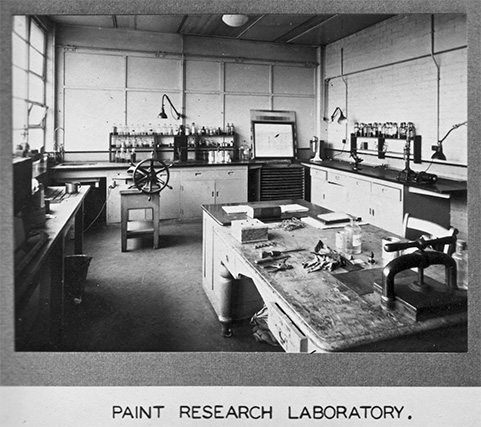

The Paint Section is responsible for the specification and testing of paint materials, some 4,000 samples being dealt with each year. It is also concerned with the routine control of the manufacture of certain cleaning agents. It cooperates with other Departments on questions relating to the choice of materials and methods of application and it conducts research on improved materials, new methods of testing and better methods of application. For the purpose of easy control, the work is carried out by three Sub-sections, one concerned with routine work, another with application and exposure records, and a third with research.

The building itself is of modern design and the accommodation is arranged as follows:-

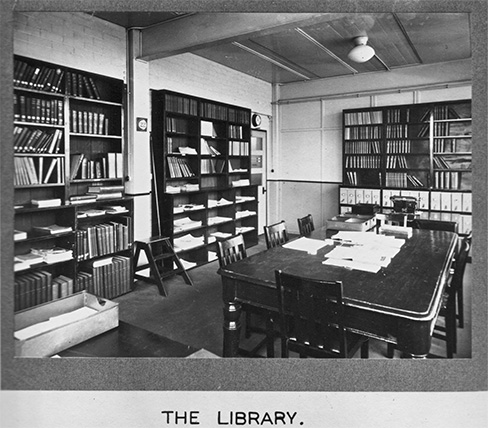

On this floor are located the Offices of the Engineering and Metallurgical Sections, the metallurgical laboratories, a room for the testing of textiles at constant humidity and. temperature, together with a library and stores. The metallurgical laboratories consist at a metallography roam well equipped for the microscopical study of metals, a chemical laboratory for the non-routine work required in connection with metallurgical investigations, a pyrometry room in which the thermal characteristics of metals are studied and a small corrosion laboratoryadditional room, at present unoccupied, is provided for X-ray and spectrographic work in the future.

This floor is devoted to the Textile and Paint Sections, the latter section also utilising the flat roof of the building for the exposure of specimens for weathering tests. The Textile Section possesses a general laboratory and a machine room in which routine examination of samples is conducted, and a research laboratory in which investigations of a non-routine character are undertaken. The Paint Section comprises separate laboratories devoted to routine analysis, exposure testing and research work respectively.

This block comprises two engineering test rooms where the usual machines for the mechanical testing of materials are located, together with certain machines specially designed for particular investigations. The block also contains a small, workshop where apparatus and test specimens are prepared, and a furnace room for the melting, casting and heat treatment of metals. Sand testing and welding investigations are also carried out in this room.

Site contents Copyright © LMS Society, 2024

April 19th, 2024

Site contents Copyright © LMS Society, 2024