This site uses non-intrusive cookies to enable us to provide a better user experience for our visitors. No personal information is collected or stored from these cookies. The Society's policy is fully explained here. By continuing to use this site you are agreeing to the use of cookies.

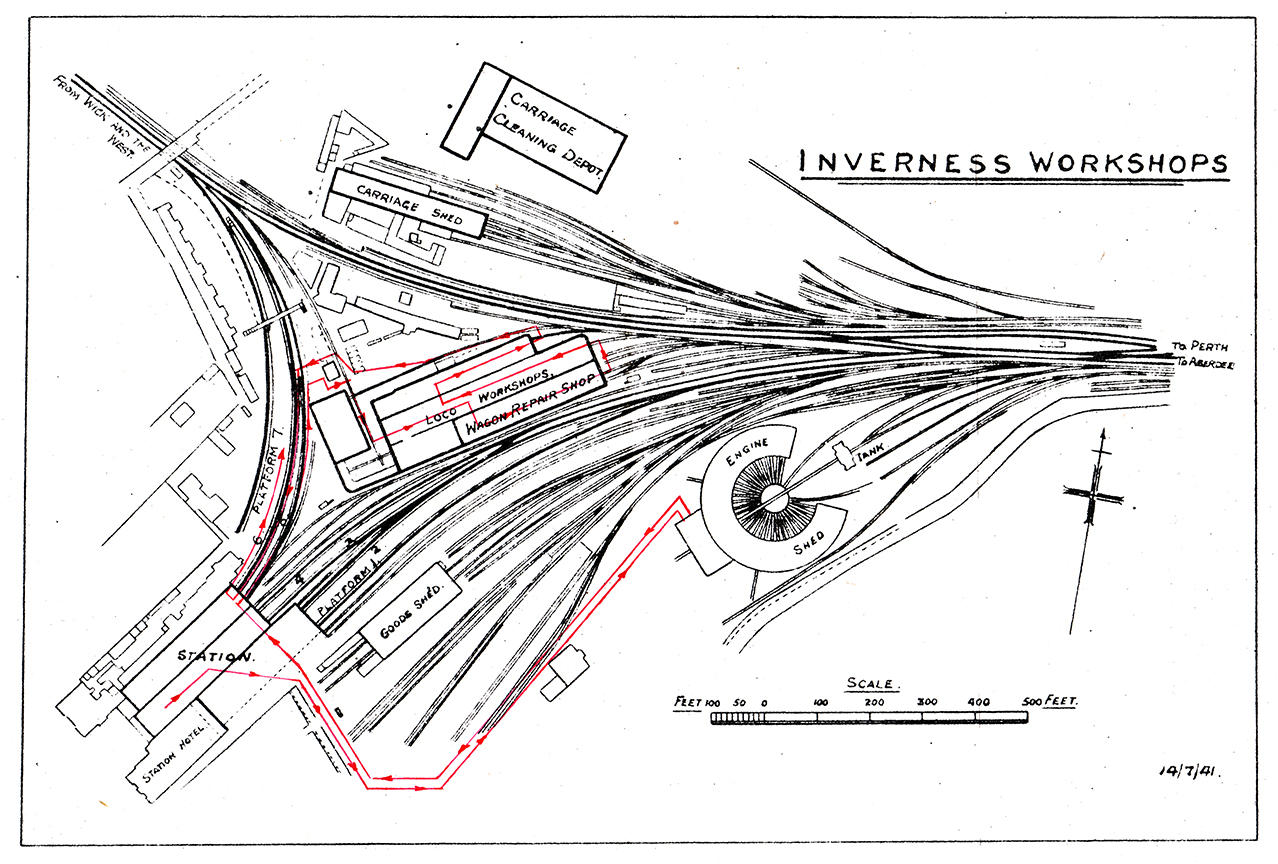

This is the original Engine Shed of the Highland Railway and is of the round house type and the only one of its kind on the Northern Division. It is the concentration depot for the Inverness area and covers, from the point of view of repairs and maintenance of locomotives, sub-depots at Aviemore, Forres, Dingwall, Tain, Helmsdade , Wick, Thurso and Kyle of Lochalsh.

The number of engines allocated is 78, 56 passenger engines and ,22 freight engines, and for the area 100 engines. Of the 56 passenger, engines 32 are of the standard Class 5 4-6-0 type.

The staff at the depot consists of 230 footplate staff, 53 artisan staff and 54 shed grades and an the area 495, 68 and 84 respectively.

Disposal arrangement at the depot are in accordance with standard practise and consist of a mechanical coaling plant with two 75-ton bunkers and a mechanical ash lifting plant. A 63-ft. turntable fitted with a vacuum tractor is installed.

The breakdown equipment consists of a 30-ton Cowan and Sheldon steam. crane and the necessary staff and usual accommodation.

The depot is adjacent to the Mechanical Engineer's workshops and for this reason neither machinery nor lifting facilities are provided at the motive power depot. The District Locomotive Supt. in charge at the motive power depot also supervises the Mechanical Engineer's workshops, including C.& W., and undertakes the repair of engines in traffic at the shed.

Any machining work, etc. which may be necessary is carried out by the C.M.& E.E. workshops.

A proposal is in hand for the provision of a new building to accommodate the office and stores as the present layout is unsatisfactory. Proposals are also in hand for the widening of the arch-way in the shed yard in order to give increased clearance for the larger type of locomotives. There is also a proposal in hand for the lengthening of the engine pits to enable engine preparations to be carried out more effectively.

The Highland Railway Workshops at Inverness prior to the Amalgemation in 1923 consisted. of' Lochgorm Works and Needlefield Works, which were built in 1857. Lochgorm was the Locomotive Repair Shops, and repairs to carriages and wagons were carried. out in Needlefield Works. Consequent on the reorganisation of the Workshops in Scotland only Light repairs were allocated to Lochgorm Works, and between 1928 and 1930 the number of staff employed in these Works was reduced from 234 to 50. .As a result, part of the Workshops became vacant end the original Engine Paint Shop was converted into a Shop for wagon repairs.

The Locomotive Repair Shops are equipped with the necessary machine -tools including wheel tyre turning lathe and whitemetalling plant , In 1942 it was found necessary to augment the output of repairs from Inverness and the staff was increased by 30 and now numbers 85 or which 13 are females. A hand-operated 15-ton hydraulic press was installed.

The output from the Locomotive Works is one Light Repair weekly and in addition work is done for the Running Sheds. Owing to there being no repair facilities at the Running Sheds, all repairs of a heavy nature which are normally done at Running Sheds, require to be undertaken at the Workshops and an average of 1.5 locomotives are repaired weekly for the Sheds by the Workshops staff.

The Wagon Repair Shop has accommodation for 40 wagons and a staff of 15. The output of repairs averages 96 Weekly.

Electricity is supplied by the Burgh of Inverness at 480/240 volts D.C.

A motor driven air compressor supplies compressed air by pipeline throughout the Repair Shops.

Steam is supplied from a locomotive type boiler.

With the transfer of the wagon repairs to Lochgorm Workshops and Heavy carriage repairs to St. Rollox, Needlefield Works became available and is now used. as a Carriage Storage and Cleaning Shed, with accommodation for 45 carriages. An electric booster for train lighting and a vacuum cleaning pant to facilitate internal carriage cleaning have been installed. The Carriage Cleaning staff numbers 27 and 320 vehicles are dealt with weekly. Minor maintenance and running repairs are carried out by a staff of six men.

In addition, the Civil Engineer's Department ; Signal and Telegraph Department and Road Motor Department were allocated accommodation in this area.

An Oil Gas Works for supplying gas to trains is situated at the south end of Needlefield Works but is meantime closed owing to the War.

A Canteen of the Nissen Hut type, for the Workshops, Running Sheds and Station staff, has been provided to the north of the Locomotive Workshops.

Site contents Copyright © LMS Society, 2024

April 19th, 2024

Site contents Copyright © LMS Society, 2024